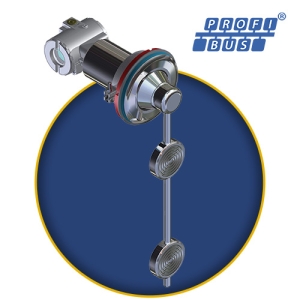

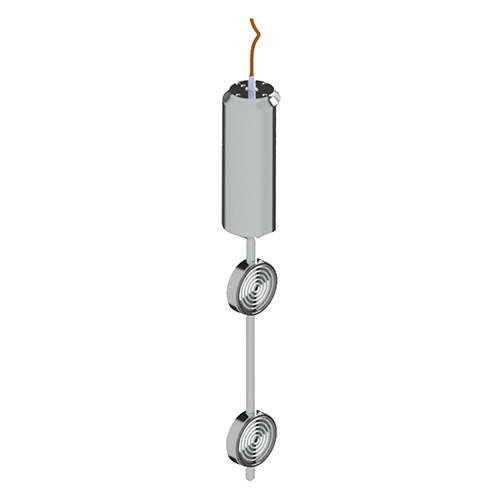

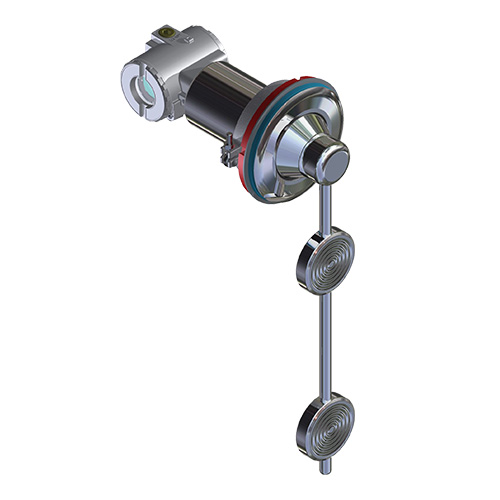

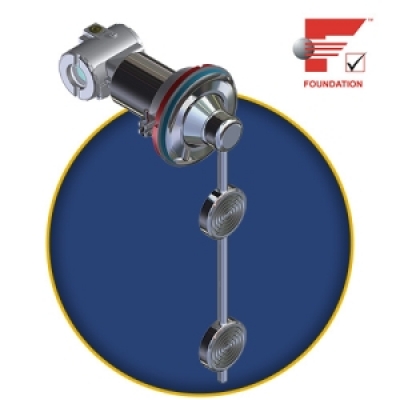

The Profibus PA DT303 Density Transmitter (Touché) is an equipment intended for continuous measurement of liquid density, directly in industrial processes. The DT303 consists of a probe with two repeating diaphragms that are immersed in the process fluid.

A temperature sensor inside the probe located between the two repeater diaphragms automatically compensates for any variation in process temperature. Special care in the manufacture and assembly of the probe and the temperature sensor means that small variations in the process temperature are quickly informed to the transmitter, which, through a dedicated software, accurately calculates the value of the process fluid density and/or concentration. According to the industrial process, the concentration measured by DT303 can be expressed in Density, Relative Density, Brix Degree, Baumé Degree, INPM Degree, Plato Degree, % Solids, etc.

The DT303 uses the Profibus PA digital communication protocol.

It can be configured using commercially available Profibus-PA compatible programs or locally using a magnetic tool in basic operations.

The DT303 was developed according to Profile V3.0.

|

Communication |

Digital, PROFIBUS PA, according to IEC 61158-2(H1), voltage mode 31.25Kbits/s with bus power. |

|

Food |

Via the PROFIBUS PA bus, 9 - 32 Vdc. |

|

applications |

Density, Relative Density, Brix Grade, Baumé Grade, INPM Grade, Plato Grade, % Solids, etc. Interface level measurement. |

|

Input |

Range 1: 0.5 a 1.8 g/cm³ |

|

Accuracy |

Range 1: ±0.0004 g/cm³ (±0.1 °Bx) |

|

Settings |

Basic configuration can be done using the magnetic screwdriver if the equipment has a display. The complete configuration is carried out with a remote configurator (eg Simatic PDM from Siemens). |

|

Functional Blocks |

1 analog input block(AI) |

|

Recommendation |

4 ½ - digits and 5 alphanumeric characters (Liquid Crystal) indicator. With configurable local adjustment (Display Block). |

|

Diaphragm |

316 SS or Hastelloy |

|

Temperature Limits |

Environment: -40 to 85 °C (-40 to 185 °F) |

|

Static Pressure Limit |

70 kgf/cm² (7MPa) (1015 PSI) |

|

Humidity Limit |

0 to 100% RH |

|

Process Connection |

Industrial Model: Stainless Steel Flange 316 ANSI B16.5 |

|

Hazardous Area Certification |

Explosion proof, weather proof and intrinsically safe, CENELEC and FM standard (pending). |

|

Mounting |

straight or curved |

|

Weight |

Sanitary Model: 4.5 kg (10 lb) - Industrial Model: 8 kg (18 lb) |

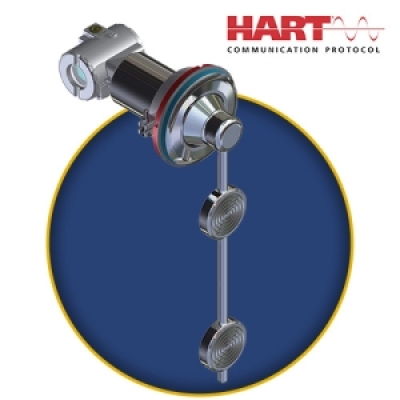

The SMAR Product File Library contains several libraries that can be used in integration with other SMAR equipment in various applications (of different communications protocols such as: HART, Profibus and Foundation Fieldbus).